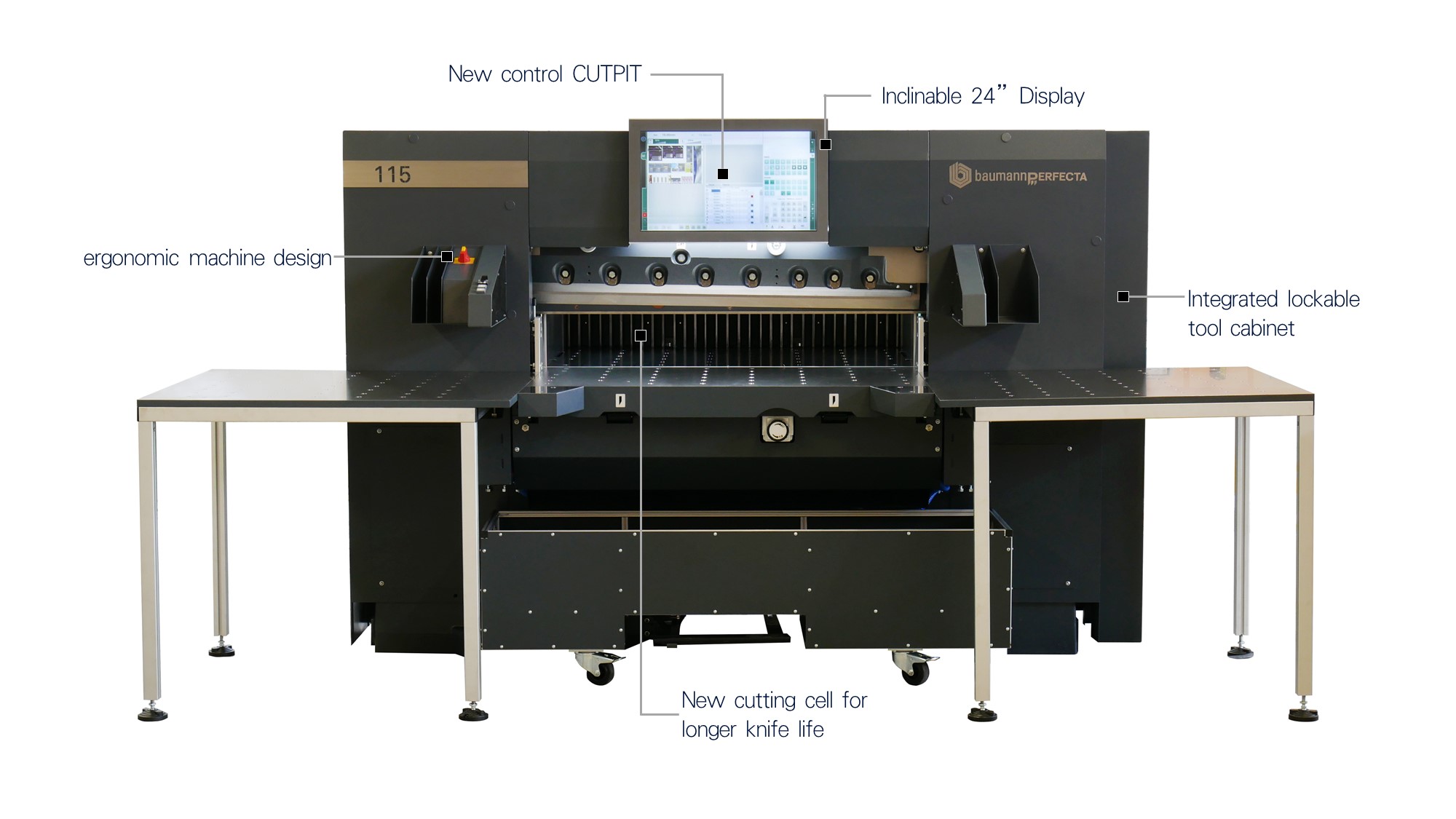

High-speed cutter – Precision and Performance

For the cutting widths 80 | 92 | 115 | 132 | 168 | 225 cm

Quality Made in Germany

The baumannperfecta high speed cutters are completely developed in Germany and manufactured at our plant based in Bautzen, Saxony. The robust basic construction of the machine frame ensures a smooth run and precise cutting results. The used components and parts, as for example the low-wear spur gearings, are designed for continuous operation so that the machines may run in three shifts, around the clock. Highest safety standards including GS and CE certification ensure safe operation for human and machine.

Perfect cutting results

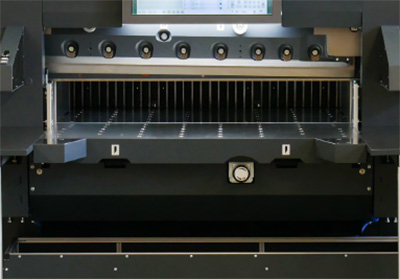

Precision and performance characterize the baumannperfecta high speed cutters. Thanks to the easy operation and process image display of the actual job, the operator has full control over the actual cutting process. The newly developed cutting cell with the innovative, active damper system automatically regulates the cutting pressure, thus offering a much longer knife life. Like this, costs for both – knife sharpening and spare parts – are considerably reduced.

High availability

The high speed cutters are designed for a 3-shift operation. The systems support you in maintenance work such as changing knives, lubricating, cleaning, etc., which are shown in the new control system by animations that guide the operator. An additional sensor system monitors the work steps during maintenance and thus prevents errors and the resulting breakdowns. This extensive service package is supported by the possibility of a remote service via remote maintenance to be able to act much faster. Moreover, each machine is equipped with an integrated, lockable tool cabinet containing necessary tools for knife change and maintenance works. Another innovation is the full coverage of the rear table, which prevents direct access to the back gauge. The cover is not only used for safety, but also ensures the drive spindle and the guide to remain free from dust and dirt.

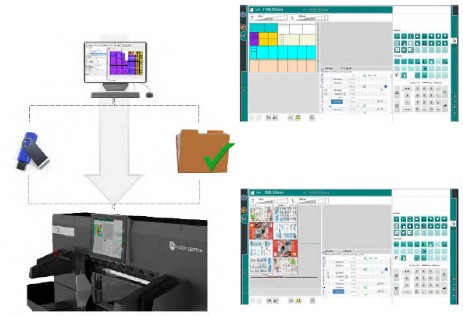

Cutting 4.0

CutTronic

CutTronic Plus

Your advantages with CutTronic Plus

- The use of pre-press data in CIP 3 / CIP 4 format

- Creation of cutting programs with all cutting formats and commands

- No incorrect cutting dimensions through automatic or guided programming

- Variable use of the cutting program on different systems

- Checking the jobs by real image display

Straight 2 Cut

The processing takes place directly in the high speed cutter. The prepress data is scanned via barcode and converted into cutting programs directly on the cutter.

- CutTronic – pre-press data is automatically converted into a cutting program

- Hotfolder – fast and easy connection of the machine to the network

- Barcode-reader – direct opening of the order file without searching

- Graphic process visualization directly on the display

Straight 2 Cut Plus

- Creation of cutting programs with all cutting dimensions and commands

- Avoidance of incorrect cutting dimensions and by automatic or guided programming

- Variable use of the cutting program on different systems

- Use of pre-press data in CIP 3 / CIP 4 format

- Real image display / PNG

- Transformation of the image (rotation/mirroring)

- PDF-converter (optional)

Networking | MIS connection

High-speed cutter at a glance

Features

- Working height 900 mm

- Stainless steel table surface with air for all cutting width

- Rear table cover made of acryl glass

- False clamp with hydraulic pressing

- Automatic pressure regulation via touchscreen

- Standard false clamp covering (80/92/115/132: 57 mm | 168/225: 77 mm)

- Safety measurement control according to CE-Norm

- Self-monitoring safety light barrier

- CE-mark, GS-certificate

- Pile support

- Lockable tool cabinet with tools

Options

- Cutpit control with 24“touchscreen

- CutTronic and CutTronic Plus for the processing of CIP3 / CIP 4 / PPF files

- Cutting programs via scanner with Straight 2 Cut and Straight 2 Cut Plus

- Barcode-Scanner

- MIS-connection

- Optical cut indicator with LEDs

- Holding down device and air in front of the knife

- Automatic waste disposal ASE

- Cutting and side tables

- Swivel/tilting back gauge

- Air tables with micro nozzles

Optional equipment for system solutions

- Loader and unloader (BB / BA)

- Transport and transfer systems

- Press-Stations (BPS)

- Buffer systems (BVP / BMR)

- Automatic joggers (BSB)

- Fully automatic jogging machines (BASA)

| 80 | 92 | 115 | 132 | 168 | 225 | |

|---|---|---|---|---|---|---|

| Cutting width [mm] | 800 | 920 | 1150 | 1320 | 1680 | 2250 |

| Rear table length [mm] | 920 | 920 | 1150 | 1325 | 1680 | 2700 |

| layer height up to [mm] | 120 | 120 | 165 | 165 | 165 | 165 |

| Smallest cut [mm] | 18 | 18 | 20 | 20 | 26 | 110 |

| Smallest cut without cover plate [mm] | 57 | 57 | 77 | 77 | 77 | 110 |