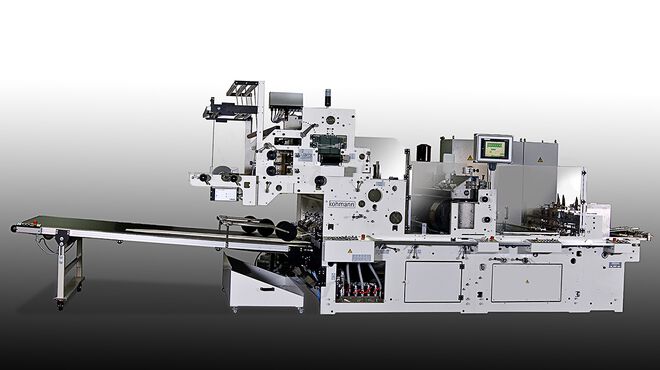

Window Patching Machine for Cardboard Packaging

– for largest blank sizes, highest volumes at highest speeds, open and versatile

Our window patching & lining machines are very easy to operate and to maintain and are made for high stress conditions. Besides the basic version we offer more than 20 different designs always suitable for various operations and multipley expandable.

The basic machine includes:

- New servo technology for the timed belt feeder

- All cylinders are driven directly by servo motors

- Glue unit with separate drive

- Input and automatic adjustment of carton relevant dates are made via a large color operator interface panel

- Storage of more than 4000 carton data for repeat orders is possible

- Advance and retard of the stereo cylinder to the carton is carried out from the operator side

- Right/Left adjustment of the stereo cylinder is carried out from the operator side even with 2-stream operation

- Max. 4-up operation possible

- Larger size ranges for 2-up and 3-up operation

- Micro-fine adjustments of board to glue and foil position whilst machine is running

- Online maintenance via modem worldwide

- Up to 2 streams possible

- Operator friendly

- High production quality

- Minimal change-over times due to computer control

- Computer-driven production control system with automatic adjustment

- Maintenance free drive concept

- The machine is accessible for adjustment and maintenance work

- Infenitely variable delivery speed by separate drive

- All-purpose due to the ability to add extra modular devices

Highlights

Normal window

Continuous perforation

Intermittent length slitting

Form slitting

additional option „Rotary profile knife station“

Pre-printed foil

Inner lining

Sealed inner tube

additional option „Tube forming station“

Bag-in-the-box coming from the reel or as a blank

Carrier handle and/or tear strip

Scoring with punch-out coming from the reel

additional option „Punching & Scoring unit“

Scoring with punch-out

Inner partition placement